MY PRODUCTION PROCESS

The production process involves a whopping 26 steps. There was a time when I had 34 steps. Then it was 23. My aim has always been to increase quality, minimize error and wastage, and decrease time spent on each task.

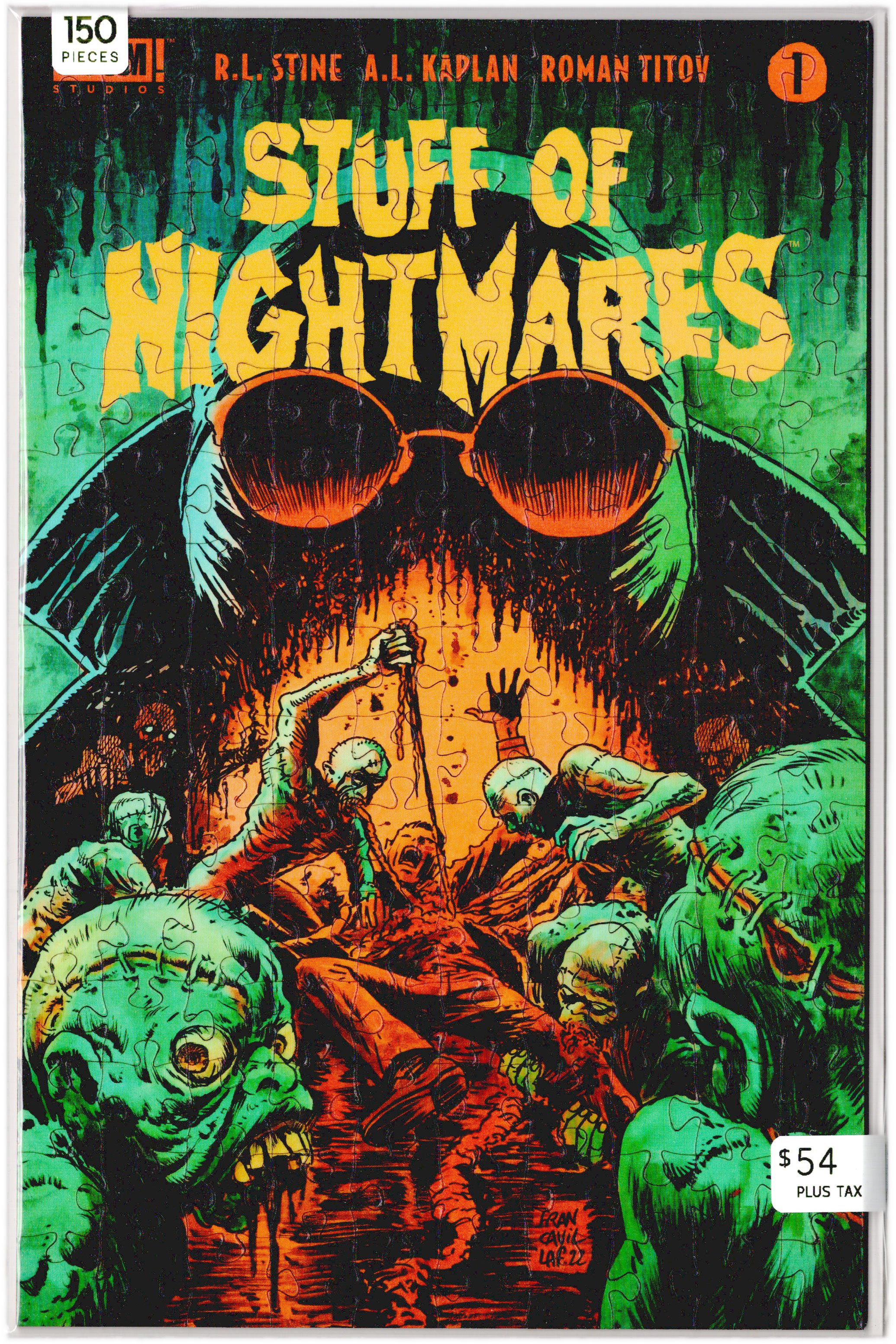

Comic books are deconstructed, cleaned, heat-pressed, laminated, and permanently bonded to 1/8” mdf using my own mounting tools and techniques. The mounted comic is laser-cut using a fully-interlocking puzzle pattern comprising a completely unique set of joinery.

Check out the How It’s Made video and decide for yourself the level of craftsmanship that goes into creating a Puzzled Comic.

I spent many months developing my concept, testing materials, comparing adhesives, cutting prototypes, experimenting with finishes, making lucky discoveries, having eureka moments, and going back to the drawing board more than once. I cut many dozens of puzzles, and handled thousands of puzzle pieces before I was satisfied with my proof of concept.

I started production in earnest, creating several large batches of Puzzled Comics, each one being an improvement on the previous. Expand a section below for a dive in my batches.

Did I mention I design all my own puzzle patterns? Scroll down for more on the patterns.

BATCH 1

I created my first large batch of Puzzled Comics and began to sell them in craft markets in the California Bay Area. They were an absolute hit with puzzle fans and comic fans alike.

Some of the remaining puzzles from this first batch are available in my shop. They all have a textured laminate surface, and their kerfs are thick compared to the subsequent batches.

Types of substrates include plywood, HDF and MDF. The puzzle backs are unfinished; some are sanded, varnished, or coated with paper.

BATCH 2

Never satisfied, I continued to refine my production process. I developed and constructed my own tools to save time in certain steps, and greatly reduce the chance of error in others. I created new methods and discovered new techniques along the way.

I also changed my adhesive lamination method, which was a game-changer.

Puzzles from the second batch all have the following characteristics: MDF substrate, unfinished back, and normal kerf. The surface laminate is either glossy or matte.

BATCH 3

I thought I was done finessing my process, but the evolution of the Puzzled Comic wasn’t over. It still isn’t.

In my quest to narrow the kerf and tighten the fit of the puzzles, I developed a new technique to further decrease the laser kerf; I began to cut the puzzles face down, like in the video. I added a couple steps to minimize any chance of error in alignment.

Puzzles from the third batch all have thin kerf. I also decided to nix the glossy laminate: a matte finish is more my style.

BATCH 4

And then Covid happened…

ORIGINAL PATTERNS

All the patterns available here are designed in-house. Not even for a minute did I consider using an automated puzzle-pattern generator. There are plenty out there – and one or two are scripted beautifully – but all churn out patterns that lack personality, and are frankly boring.

I created my own master puzzle pattern: a fully-interlocking matrix with a completely unique set of joinery, designed with subtle differences in the mortises and tenons. The master pattern comprises 75 horizontal paths and 75 vertical paths containing 5,625 unique pieces.

Depending on the size of the puzzle and the number of pieces, I isolate varying sections of the master pattern to create a unique matrix for each comic book cover. Once all the available sections have been used, I create a new master pattern by randomly re-ordering, rotating, or mirroring all 150 paths.

Sometimes I’ll add an effect to a matrix (such as a bubble, pinch, or wave) to enhance the puzzle pattern to make assembly more challenging. The unique joinery in the master straight pattern has spawned new puzzle styles you’ve possibly never seen before such as diagonal, spiral, elibelinde, and waterfall patterns.

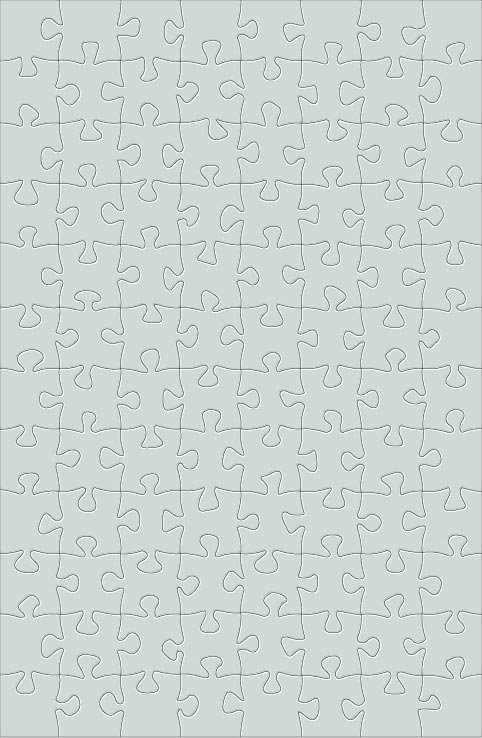

STRAIGHTs

Straight patterns are the old-fashioned puzzle patterns that you’re accustomed to and don’t require much explanation.

Since the master pattern is a straight grid, it only takes a few minutes to create unique matrixes for each comic book cover. This is the easiest pattern to replicate and customize, and one of the easier patterns to assemble.

Straight patterns make up the majority of my inventory.

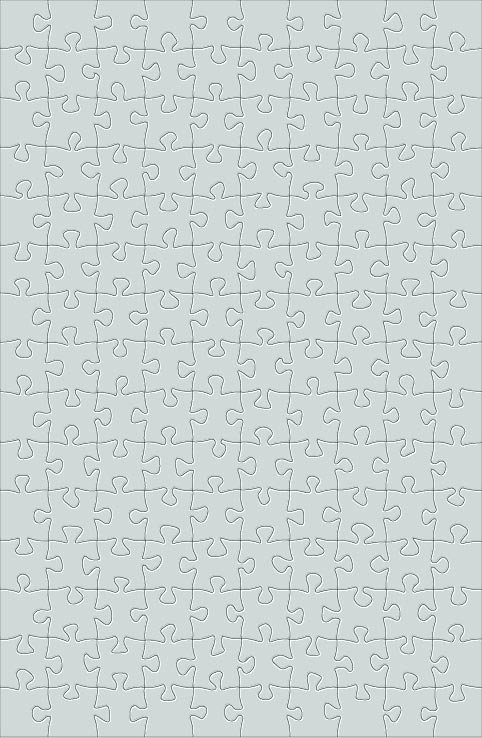

DIAGONALs

Rotate the master pattern 45° and voilà, you’ve got a diagonal pattern. Whereas straight matrixes take a couple minutes to create, diagonal ones require more time to prepare for laser cutting.

Diagonal matrixes are more challenging to assemble, especially if you like to start your puzzle assembly by connecting all the straight-edged pieces. You can’t do that with diagonal patterns — the straight-edged pieces don’t connect to each other, except at the corners. It’s best to assemble diagonals from the inside out.

SPIRALS

Although this master spiral pattern looks nothing like the straight and diagonal styles, it actually contains the same mortise/tenon joinery from the master straight pattern.

The spiral pattern was simple enough to construct, but very time-consuming. Additionally, it takes a lot of time to isolate a given section of the master spiral pattern, and to prepare it for laser cutting. For that reason there’s a limited number of spiral puzzles available in my shop.

They are also quite challenging to assemble — take them apart at your own risk.

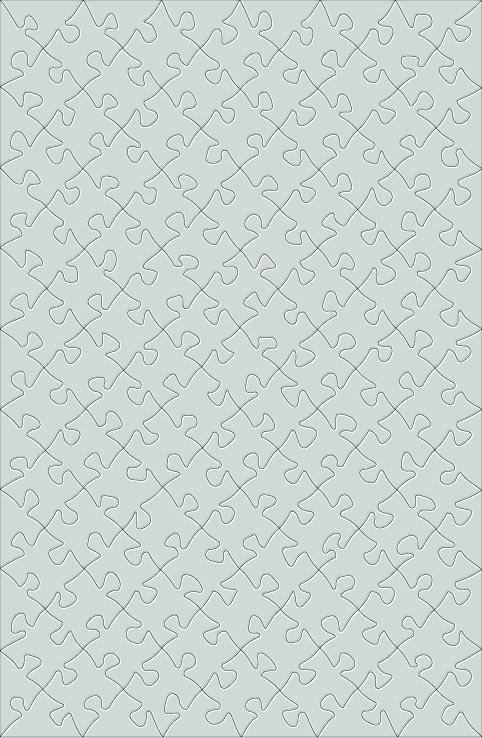

ELIBELINDE

This pattern is a modified straight matrix: the intersection of each horizontal and vertical path is alternately rotated clockwise or counter-clockwise.

Transforming a straight matrix into an elibelinde can be a lengthy undertaking, especially if there are a lot of pieces.

The name of this puzzle style is an homage to a particular pattern used in Turkish carpets and kilims. Eli belinde means ‘hands on hips’ in the Turkish language. It’s a shout-out to my own heritage, and is a fitting name for a pattern only available here at Puzzled Comics.

WATERFALLS

At a glance, the waterfall pattern might look like a bowed version of the straight pattern. It is bowed, it’s also stretched along the top x-axis. The result is a pattern that reminds me of a waterfall. It has more pieces along the bottom than it does along the top, and the stepped transitions between horizontal rows of pieces can create some funky truncated shapes on the sides of the puzzle.

Given the symmetrical nature of the pattern, there’s a limit to the number of viable sections within the master pattern. The waterfall effect only works if the isolated sections are centered along the horizontal axis.

Consequently, puzzles cut in a waterfall pattern tend to be rare. Get your own before supplies dry up.

All puzzle patterns and pattern effects by me. ©2020–2023 Ozan Berke

I am not affiliated with, or otherwise endorsed by, the publishers of the comic books used in the production of Puzzled Comics. The use of trademarked character names, the names of the artists , and their publishers, are only for descriptive purposes. I make no commercial claim to their use, or suggest any sponsorship or endorsement.

Puzzled Comics contain delicate pieces and are not suitable for kids younger than seven.